King Steel Rolling Mill

Incepted in the year 1978, King Steel Rolling Mills is one of the leading manufacturers, exporters and suppliers of industrial supplies, which are used in varied industries such as construction, Scaffolding, Automobiles, Cement Plants, Power Transmission Industries , Bridges and Fasteners industry. Under the profound guidance of our mentor Mr. Rakesh K. Gupta....

- bound Delivery

- Transparent dealings

- Customer Satisfaction

- Continuous Improvement

Happy Clients

Total Workers

Total Production

Total Experience

Our

Products

We are recognized as well established entity in building, construction and industrial sector and have expanded our product lines and categories in construction equipment like mobile tower, scaffolds, fasteners, hand tools, bicycles, dams, power transmission sectors, bridges, railways and malls. We provide complete chain of steel.

Get in Touch

-

-

Our Address

G.T.Road (Sirhind Side), Mandi Gobindgarh -147301.Punjab

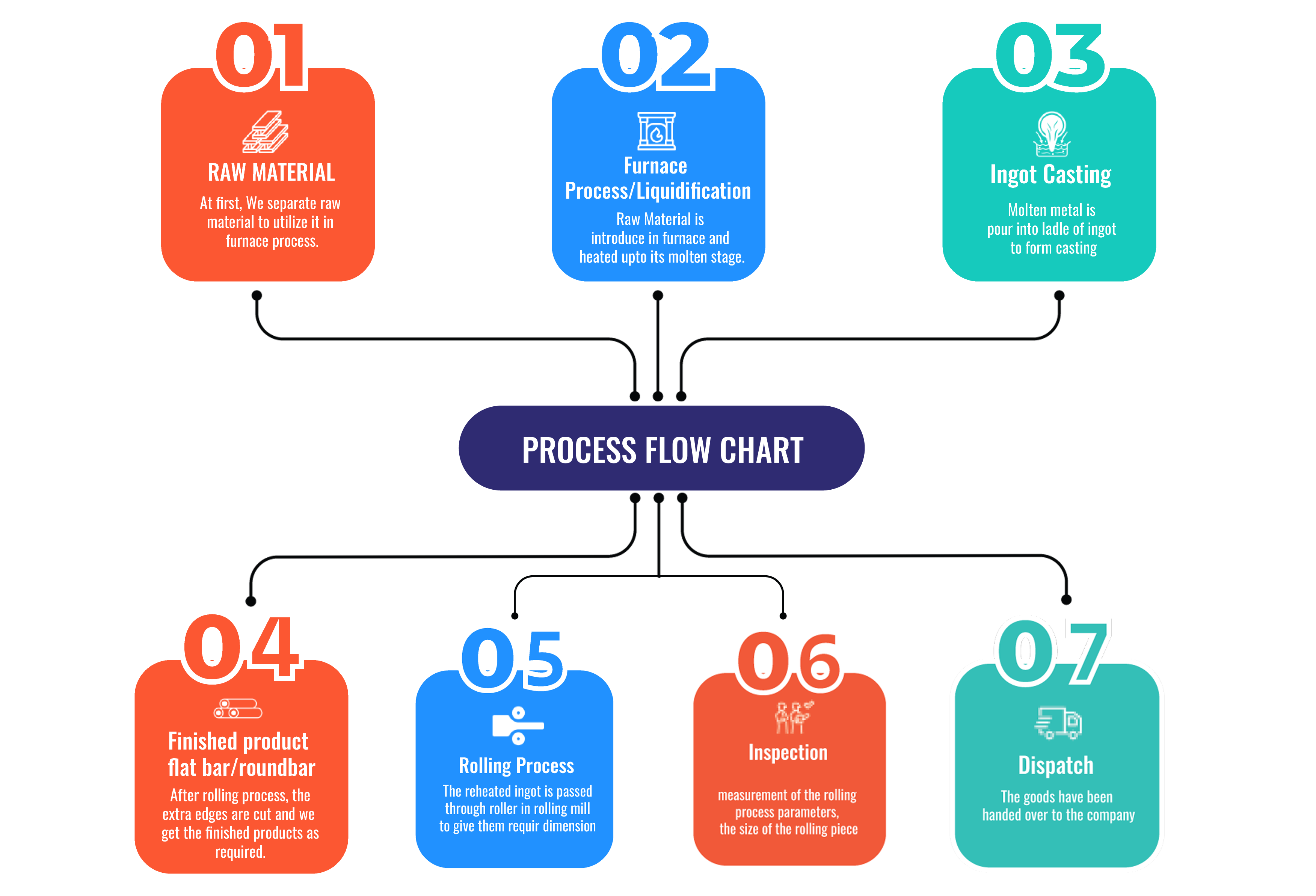

PROCESS FLOW CHART

Hot rolled coils with middle and high carbon content serve as the primary raw material. To produce strips with the desired breadth for hot rolling, the coils are slit on a slitting machine. These hot rolled pieces are acid pickled for scale removal through a continuous pickling line after being slit. Depending on the desired final thickness, the rolling and intermediate annealing processes can be done as many times as necessary for medium- and high-carbon coils. After their final rolling, these coils are slit on a CR slitting machine to achieve the desired end width. The Hardening/Tempering section receives these cold-rolled and slit coils for additional processing.

Strips are heated in an electrically heated furnace in an airtight muffle in an inert environment, then quenched and tempered to the required hardness. Next, the pieces are edge dressed. (if desired). The grey segments from the H/T line are polished with a buffing compound or ground to a bright finish. The strips can also be colored and tempered to achieve the desired hue (blue, yellow, bronze, or golden), and they are then examined, oiled, and packaged for shipment.

What Our

Clients Say's

Contact Us Now.

procure THE FINEST CUSTOMIZED ALLOY STEEL.We make sure that our Quality Assurance prevents any mistakes and defects in any of the steel products that our clients procure from us.